One of Shropshire’s leading manufacturers of precision components has been selected to take part in a prestigious supplier development programme by Collins Aerospace.

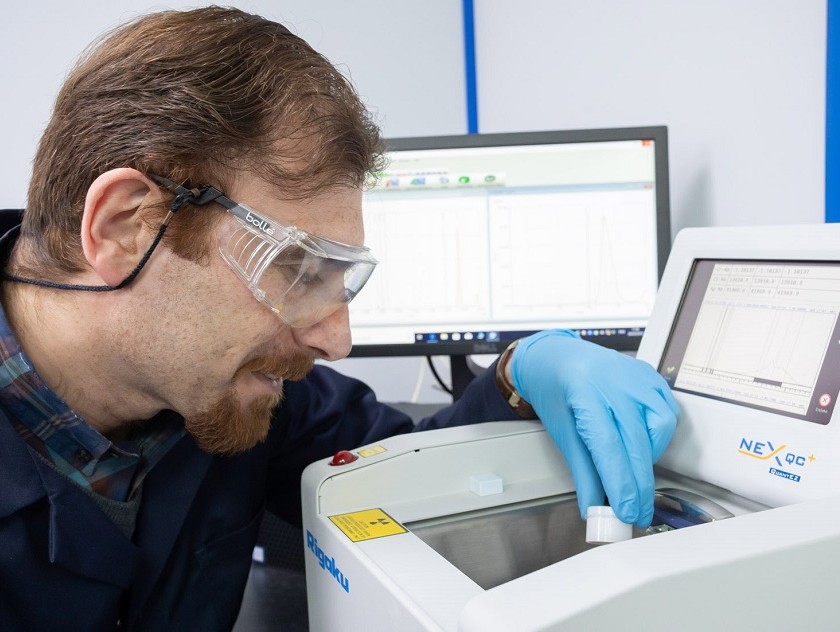

Advanced Chemical Etching (ACE) is working with the world leader in aerospace and defence technologies on a host of continuous improvement and training activities to help it strengthen its ability to supply group factories across the globe.

The company is now setting its sights on securing Gold Supplier status, which could be achieved over the next six months if it continues to meet 100% delivery on-time-in-full and stronger collaboration on root cause analysis. It marks what has been a rapid period of growth for ACE in the aerospace sector, with sales into this industry now accounting for 25% of annual sales.

Ian Whateley, managing director, said: “This is a very demanding supplier development programme and very difficult to get on to, so this in itself is testament to the relationship we currently have with Collins Aerospace.

“We have taken a top-down approach to our involvement, making sure every member of our 65-strong workforce is on board, understand what is required and how they can play a role in helping us achieve the performance requirements in terms of cost, quality and delivery.

“The support we have received to help us on this journey has been world class and it has been a real team approach from both companies to identify areas to work on and new opportunities to pursue.

“When we achieve Gold Supplier, we will then appear on Collins Aerospace’s worldwide portal as its preferred etching company. This will be massive for ACE, as it means we could be used by any international division across the group, not to mention the profile it will give us amongst the rest of industry.”

Richard Jones, supplier development manager at Collins Aerospace, has been working hand-in-hand with Advanced Chemical Etching.

“It all starts with The Quality Clinic, which provides an insight into investigation, detection, root cause analysis and the implementation of preventative actions to ensure we are delivering the highest standards to our internal and external customers.

“Ian and his team are fully engaged with the training I’ve helped provide and this has ensured the right culture is in place, where a ‘quality first’ mentality is embraced and driven by every single member of staff. The company is well on its way to achieving the Gold Supplier status and, importantly, becoming ‘best in process’ across the etching world.”

ACE offers development of prototype components, pre-production and volume fulfilment to customers in aerospace, automotive, electronics, medical, telecoms and renewables. The scope of its activities is far and wide and can include anything from safety critical components for aircraft and F1 cars to meshes and electronic connectors and even frames for designer glasses.

All parts are developed and manufactured at its main site in Telford, where it has recently spent £850,000 on pre and post cleaning machines and new auto loaders to support a move to ‘lights-out manufacturing’ in some parts of production.

Covid-19 accelerates disruptive tech in aerospace

Major expansion drive launched after orders surge

Gateway organisation will help boost job opportunities

3D Printz teams up with South Korean supplier

Fabweld Steel Products awarded more than £8,000

Environmental performance is rewarded once again

Fast-growing supplier signs another new distribution deal

Engineering student is promised subsidised studies and full-time job

Apprentices and employees have chance to learn new skills

Deal will create online grocery service

Experts offer advice on upskilling workforces

Automotive engineering students will have new facilities

New invention will help to reduce injuries

Firm can now expand and take on new staff

Programme has never been more important for manufacturers